Bearings are used extensively in the food and beverage industry as components in a variety of food processing and packaging machinery. Food-grade bearings must endure extreme conditions in many applications, so the life and performance of bearings used in these applications are influenced largely by the decisions of designers and engineers. Design considerations that may impact a bearing’s durability in food-grade applications include material, lubrication type, and shielding options.

Bearings used in food processing and packaging must withstand harsh operating conditions and equally harsh cleaning procedures designed to comply with stringent hygiene standards and government regulations. Common conditions bearings must tolerate include:

Bearings used in food processing and packaging must withstand harsh operating conditions and equally harsh cleaning procedures designed to comply with stringent hygiene standards and government regulations. Common conditions bearings must tolerate include:

- Contact with corrosive food and beverage ingredients

- Exposure to cleaning chemicals

- High-pressure washdowns

- High environmental humidity

Regulatory Requirements of the Food Processing & Packaging Industry

Food producers in the United States have been subject to manufacturing and processing rules and regulations for decades, and these standards continue to evolve. State and federal agencies regularly impose new regulations upon the U.S. food processing and packaging sectors.

Poultry or meat processing facilities fall under the jurisdiction of the USDA Food Safety and Inspection Service, while the FDA oversees any other food-related packaging or processing operations. Federal agencies handle the majority of regulatory oversight, with state and local agencies playing an active role in supervising and enforcing rules for food processing and packaging businesses.

Materials used in food packaging or production must comply with federal, state, and local codes and requirements. This typically includes any bearings and lubricants used within processing equipment.

Key Components of Food Grade Bearings

The following factors must be addressed to create food-grade bearings that comply with federal, state, and local regulations:

Lubrication

Like most bearings, lubrication plays a crucial role in extending the life and improving overall performance of food-grade bearings. Food processing and packaging equipment require special lubricants that can withstand the severe conditions created by the cooking process, as well as the frequent washdowns required to maintain sanitary conditions.

The choice of lubricant depends on the various conditions the bearing will be subjected to, as well as any relevant regulatory requirements for the specific operation type or product. With the possibility of the lubrication coming into contact with food products, the lubricant used must meet specific regulatory standards.

The appropriate lubrication depends entirely on the specifics of the application. In general, lubricants should facilitate good resistances to corrosion and abrasion. Lubricants used in high-temperature applications must maintain oxidation stability at standard operating temperatures.

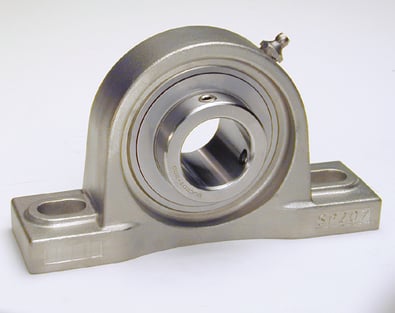

Materials

Not all metals are suitable for use in food processing and packaging. The materials used in the manufacture of food-grade bearings should be of the highest purity available to create a bearing that is durable and highly resistant to corrosion. Metals such as stainless steel are used extensively in food processing.

Though more expensive, nitrogen-enhanced martensitic stainless steel bearings are often selected for applications with extremely corrosive elements. These bearings display up to five times the corrosion resistance of standard stainless bearings.

Seals

Bearings in food processing and packaging plants are continuously exposed to liquids and various types of debris, as well as frequent wash downs. Sealed or shielded bearings are critical for keeping the lubricant in the assembly while keeping unwanted debris and fluids out of the interior of the bearing assembly.

The seals and shields used must also meet food industry regulations and guidelines for use with fluids, foods, and chemicals so they won’t contaminate any product. Nitrile rubber and Viton are the most common seal materials for food-grade bearings, and they may also be shrouded in stainless or galvanized steel. The design and construction of the seal can significantly improve the bearing's ability to function in extreme environments.

Food Grade Bearings from Emerson Bearing

At Emerson Bearing, we provide replacement bearings and MRO solutions for an expansive range of New England-based food packaging and processing operations. We work closely with customers of all sizes to provide innovative bearing solutions tailored to the unique needs of each use case. To learn more about food-grade bearings from Emerson Bearing, contact us today.