Ambient temperature is extremely important when choosing a bearing. Whether due to friction, electrical current, electromagnetic induction, or extreme external conditions, bearings are often required to perform in high-temperature environments while maintaining dimensional stability. Emerson Bearing is providing this quick article to help you understand the essence of what it takes for your bearing to take the heat.

Emerson Bearing Blog

Emerson Bearing is a leading supplier of high-quality ball and roller bearings. We have established and maintained our reputation for over five decades, delivering bearings to global and domestic customers. Our team of experts ensures each customer receives the most suitable bearings for their application. One of the major industries we serve is robotic automation. Read on to learn about our precision bearings for robotic applications.

Topics: precision bearings, bearings

Having Bearing Challenges? Talk with Emerson: Solve Your Pricing, Delivery & Technical Issues

Posted on November 23, 2022

A detailed understanding of bearings is crucial for selecting and sourcing the correct bearing. It's difficult for a customer with little or no knowledge of bearings to make the right decision. That's why it's best to partner with a company or service with experience in sourcing, pricing, and delivering bearings.

Topics: bearings, ball bearings

There is a vast array of bearing types and sizes for a good reason: every application has unique needs and specifications, and it’s important to use the right bearings for the job. When you work with a trusted bearing provider, you’ll have a large inventory of roller bearings, ball bearings, contact bearings, and more to choose from, and you’ll have the opportunity to create custom solutions. Your provider should be able to source and distribute your bearings quickly and efficiently, help you make decisions, and offer you the same standard bearing at various price points depending on where it’s being sourced from.

Topics: bearings, bearing rating, cost-effective

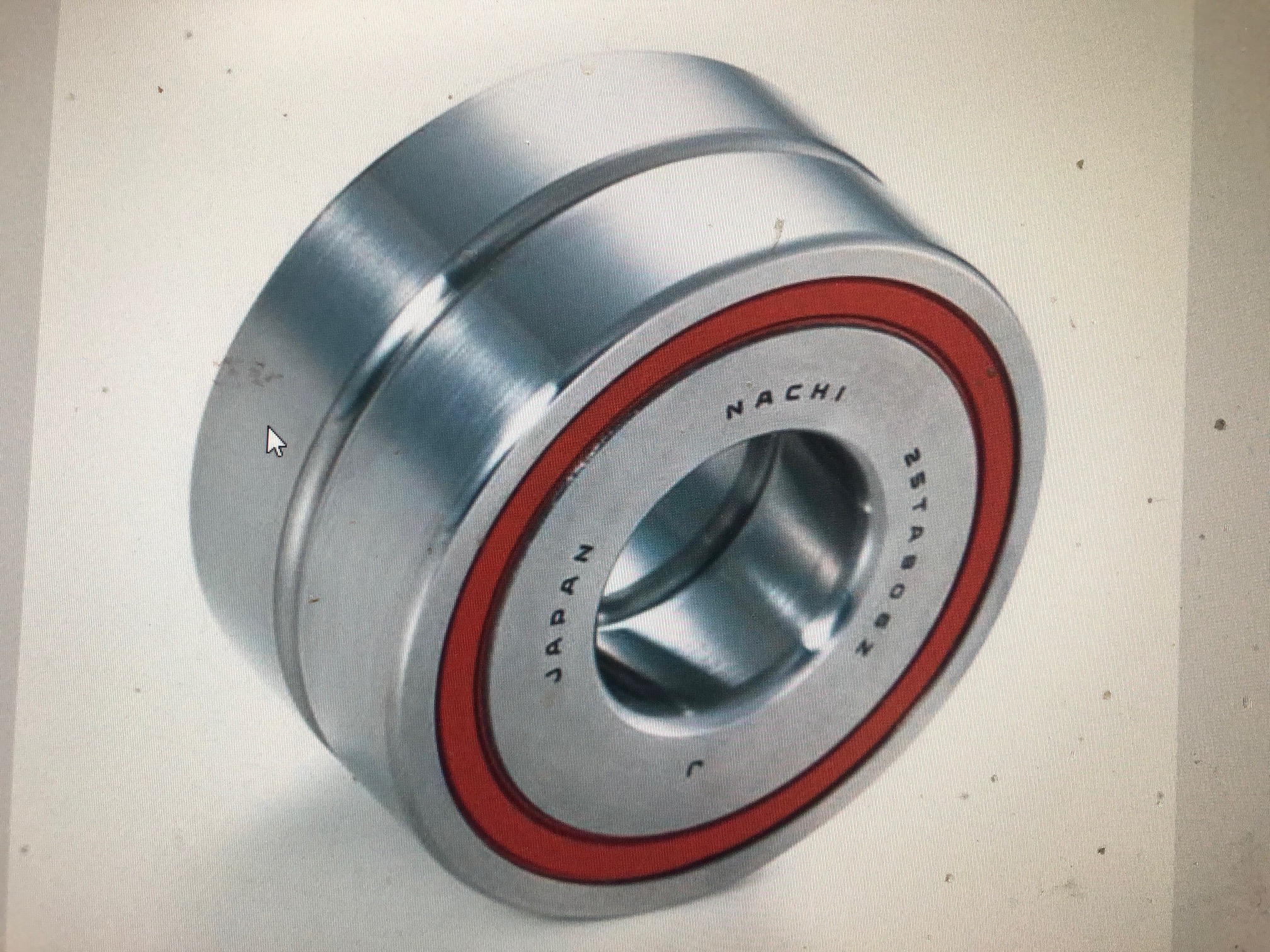

From the simplest home appliance to the most complex industrial equipment, precision engineering is essential for safe, reliable moving parts. Connections must allow unrestricted movement, which is where roller bearings come in. Like ball bearings, roller bearings are meant to minimize friction while managing a load, but instead of having point contact, roller bearings have line contact. This gives them greater shock resistance and capacity, and they come in a variety of shapes, including cylindrical, tapered, spherical, and needle profiles, to suit various applications.

Topics: roller bearings, bearings

Modern machine tools are used to shape parts from wood, ceramic, metal, and other materials into a desired shape or form. For optimal accuracy and reliability, machining equipment requires high quality precision bearings, such as ball screw support bearings. Known for their durability and long lifespan, ball screw support bearings offer superior axial strength and the ability to tolerate high thrust loads without sacrificing accuracy, making them well-suited for high performance actuators.

Topics: emerson bearing, bearings

In some industrial jobs, standard bearings simply can’t provide the precision needed for the application. This is where extra precision bearings come into play. These bearings allow for extra fine tolerance and precision, and are ideal for applications with stringent requirements for speed (RPM) and guidance accuracy. There are two primary types of extra precision bearings: deep groove bearings and angular contact bearings.

Topics: bearings, ABEC Classes, ABEC Parameters, extra precision bearings

In sensitive food-grade applications and corrosive environments, selecting the proper bearings is critical for ensuring optimal system longevity and reliability. In these harsh settings, bearings must provide high performance and durability without the need for frequent maintenance or replacement.

Over the years, bearing manufacturers have developed a range of solutions designed to stand up to the general wear and tear inherent in applications involving constant exposure to corrosive elements or ongoing, high-pressure washdowns.

For instance, stainless steel bearings, solid lube, and seals and slingers can be used to create unique components that deliver high performance and a long life span while resisting bearing contamination.

Here at Emerson Bearing, we’re proud to offer NTN Sentinel Series stainless steel bearings, which are specifically designed for use in these food-grade settings.

Topics: bearings, split roller bearings, split bearings

No matter what the specific application or industry focus, efficiency is key for ensuring optimized operations in industrial facilities. But high efficiency means more than just cutting-edge equipment and comprehensive quality assurance; it also means making use of high-quality, reliable components in all machinery and equipment. Doing whatever it takes to keep the machines running.

Split roller bearings, in particular, offer great versatility and wide-reaching benefits. Allowing for reduced maintenance and fewer replacements than traditional solid roller bearings, split bearings are used in a range of applications to reduce downtime, save on costs, and increase overall safety. Quick and easy to install and replace, these versatile components are essential for any facility requiring consistent operational efficiency. They are available as direct drop in replacements dimensionally to standard SAF Spherical Roller and Cylindrical Roller units with both metric and inch shaft dimensions.

Topics: bearings, split roller bearings, split bearings

Cam followers and cam follower bearings are essential components in many industrial operations involving conveyors or process transfer lines. Used in a wide range of industries including power generation, metal processing, packaging, food processing, transportation, automation, and recreation, cam followers are able to be easily mounted and are well-suited for many cam or track roller applications with moderate loads and shock.

Proper use of cam follower bearings helps ensure optimized performance and longevity. Developed to replace the standard bearing and bolt configuration, this type of roller bearing is designed to be more efficient, more reliable, and considerably easier to maintain than their predecessors. At Emerson Bearing, we have the expertise to walk you through the process of choosing the right bearings for your specific needs.

Topics: bearings, cost-effective, cam follower, cam follower bearings, yoke rollers

Be the first to know about all things bearings!

Subscribe to our blog to receive the latest company and industry news right in your inbox

-1.jpg)