Ball and roller bearing internal clearance is the total distance the inner or outer ring of a bearing can move when the opposite ring is fixed. A certain clearance is needed to allow for adequate movement between rings. Your bearing clearance can improve or hinder overall bearing performance. Over time, it can also affect the lifespan of the bearing.

Let's examine what bearing internal clearance is, why it matters, and how to select the correct clearance for your needs.

Why Does Bearing Internal Clearance Matter?

Bearing internal clearance is critical to maintain the bearing’s efficiency in operations. The internal clearance determines whether rolling elements move in a rolling or sliding motion, which affects the bearing's mechanical efficiency.

There are two types of internal clearance:

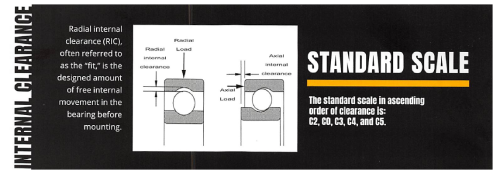

- Radial Internal Clearance. Movement perpendicular to the bearing axis

- Axial Internal Clearance. Movement along the bearing axis

Radial internal clearance can be calculated by taking the outer ring’s average raceway diameter and subtracting the inner ring’s average raceway diameter, then doubling and subtracting the ball diameter. Axial play, measured along the bearing axis, is typically about ten times the radial play value.

Proper internal clearance is critical for maintaining a stable load distribution within the bearing. This directly affects bearing performance, reducing running noise and controlling vibration levels.

How Much Can Bearing Internal Clearance Be?

The internal bearing clearance should be as low as possible, ideally a few microns or even zero after assembly. The correct clearance degree can be determined by assessing a few project-specific factors. Factors influencing bearing internal clearance include:- Application

- Temperature

- Load Conditions

Related Reading:

Bearing Internal Clearance: C0 vs. C3

Understanding the differences between C0 and C3 clearances can help you find the right bearing for your application:- C0 (or CN). The standard clearance for typical applications with recommended fits and normal operating conditions. This clearance isn't usually marked on the bearing.

- C3. A greater clearance compared to C0. This clearance is used when higher thermal expansion or specific load conditions require more space within the bearing.

Choose Emerson Bearing for Precision-Machined Bearings

Emerson Bearing has a rich history in the bearing industry, providing high-quality, precision-machined bearings for a range of applications. Our expertise and commitment to quality make us a reliable partner for your bearing requirements.

With a range of products including ball bearings, ceramic bearings, roller bearings, linear motion bearings, and super precision bearings, Emerson Bearing is ready to help you find the perfect solution for your needs.

Visit our Contact Us page or Request a Quote form to get started; we’ll work to provide the precision and quality you need.