Looking through a bearing catalog for the first time can be confusing or even a little intimidating. The numbering system is universal, and the majority of manufacturers use the same numbers for the same product. This allows for access to competitive products globally. The catalog can seem to be written in a secret code, with a series of letters and numbers that are unknown to anyone who hasn't chosen a bearing before. This blog post will help you crack the code and understand how to get the most from your bearings.

Rolling bearings are designated by codes that indicate the construction, dimensions, tolerances, clearances, and load factor of each bearing. A bearing's internal clearance indicates the intentional amount of deviation that's acceptable in a fit between dual mating dimensions, whereas its tolerance is the maximum unintentional deviation that the bearing can have compared to the nominal value. The allowance and tolerance make up the minimum and maximum interference or clearance for the bearing.

Bearing catalog codes may include one or more of the following parts:

- Basic code: This code identifies the type of bearing, as well as its bore diameter, which is the diameter of the bore's inner ring.

- Prefixes: Prefixes within a bearing number denote the bearing's basic parts.

- Suffixes: The suffix portion of a code will signify that the bearing has a unique design or feature.

What Do Bearing Numbers Mean? Basic Code

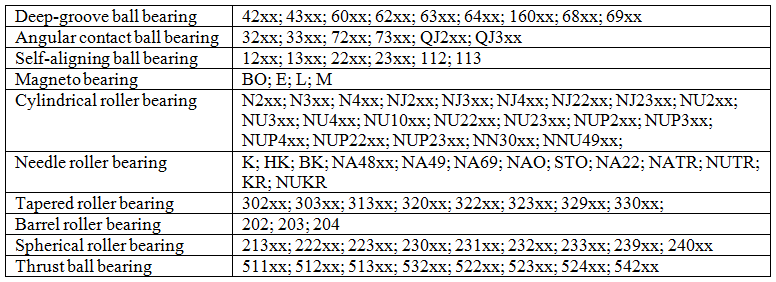

A bearing's basic code is made up of its bearing series and bore number, which signify the bearing's type and bore diameter, respectively. The bearing series may consist of letters, numbers, or both to specify its diameter series, construction, and often its width series, as well. To review the bearing series for commonly used bearing varieties, see Table 1 below.

Table 1. Bearing Series for Common Bearing Types

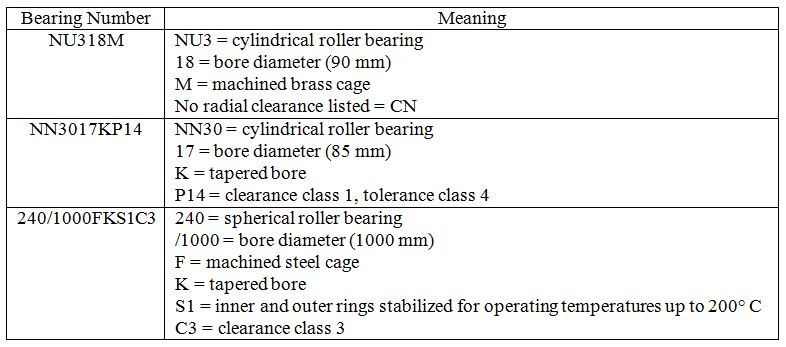

The bore number indicates the bore diameter. See Table 2.

Table 2. Example of Bearing Numbers and Codes

If a bearing number consists solely of the basic code but not any prefixes or suffixes, this indicates that the bearing is normal and falls within the typical standards for clearance, precision, and form.

If a bearing number consists solely of the basic code but not any prefixes or suffixes, this indicates that the bearing is normal and falls within the typical standards for clearance, precision, and form.

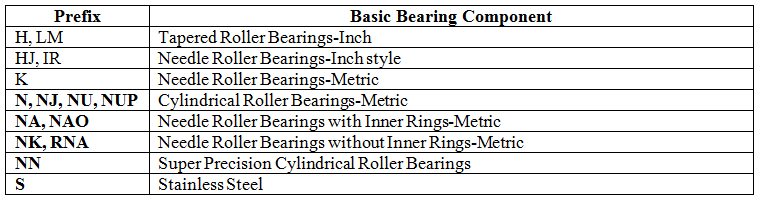

Bearing Letter Meaning: Prefixes

Prefixes indicate the primary components of the bearing. Table 3 identifies typical prefixes for bearings.

Table 3. Bearing Letter Meanings: Common Prefixes

Bearing Letter Meaning: Suffixes

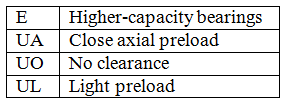

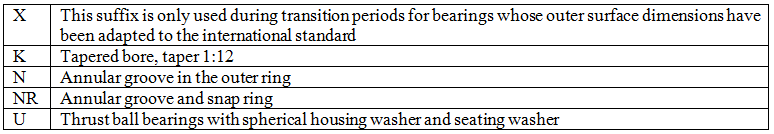

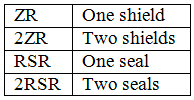

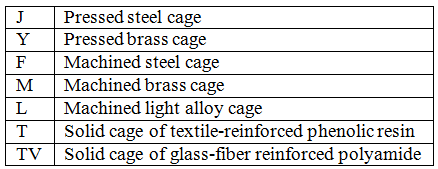

As discussed, suffixes in a bearing number denote its unique design features or qualities, such as the following:

- Cages

- Clearances

- Closures

- Heat treatment

- Noise behavior

- Outer forms

- Precision tolerances

The following tables list the most commonly used suffixes for bearings.

Table 4. Bearing Suffixes for Internal Design

Table 5. Bearing Suffixes for Outer Surface Dimensions

Table 6. Bearing Suffixes for Sealings and Closures

The suffixes that designate a bearing's shield or seal type often vary by manufacturer. However, examples of common suffixes include the following:

- ZZ: Double metal shields

- 2RS: Double rubber seals, typically non-contact seals

- DU: Double contact seals, full contact seals

Table 7. Bearing Suffixes for Cage Materials

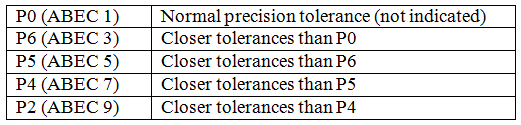

Table 8. Bearing Suffixes for Precision Tolerances

ISO 199, a universal standard, defines the tolerance classes, as well as any tolerance characteristic values, for thrust bearing varieties. The same is true of ISO 492, but for radial bearings. As of 2014, these standards now align with general ISO Geometrical Product Specification (GPS) standards, with examples including ISO 5459 and 1101.

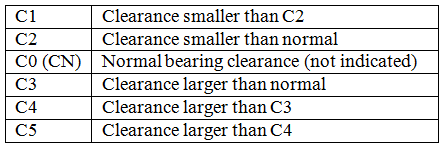

Table 9. Bearing Suffixes for Bearing Clearances

Bearing numbers combine the suffixes for bearings that have special precision tolerances and clearances. For instance, a bearing with a P6 tolerance and C3 clearance would be written as P63. Common suffixes for internal clearance indicate the following:

- C0: Normal clearance

- C2: Smaller clearance

- C3: Greater clearance

- C4: Larger clearance

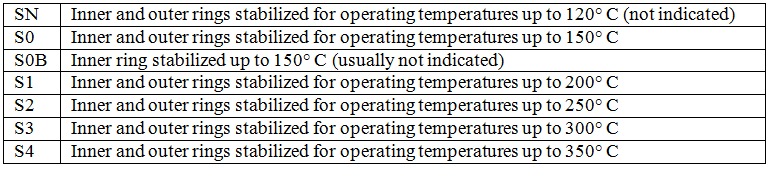

Table 10. Bearing Suffixes for Dimensionally Stabilized Bearings

Contact Emerson Bearing for Help With Bearing Numbers and Codes

For over half a century, Emerson Bearing has helped clients in industries ranging from power generation and mining to transportation and recreation find the right bearing at the right price. We offer various resources on our website to help you make the proper selection for your specific project.

Our Technical Toolbox is a library of compiled Emerson Bearing resources, with guides, charts, vendor catalogs, and more covering an array of bearing topics. We also encourage you to download a free copy of our eBook "Nomenclature Guide to Common Bearing Types." In our Bearing Product Catalog, you can review the various types of bearings and bearing accessories we have available.

Contact us for any assistance selecting the right option for your needs, or request a quote today to get started.