Ambient temperature is extremely important when choosing a bearing. Whether due to friction, electrical current, electromagnetic induction, or extreme external conditions, bearings are often required to perform in high-temperature environments while maintaining dimensional stability. Emerson Bearing is providing this quick article to help you understand the essence of what it takes for your bearing to take the heat.

What Is Dimensional Stability in Rolling Bearings?

A material's dimensional stability is its ability to retain its original shape and dimensions when faced with mechanical stress or changes to environmental conditions like temperature and humidity. Dimensional stability is critical in applications like engineering and manufacturing precision products, as inaccuracies in product dimensions could lead to a loss of structural integrity and overall quality.

In roller bearings, dimensional stability is of particular importance because imprecise dimensions will greatly impact bearing performance. Bearings with poor dimensional stability would experience greater friction as well as clearance loss, ultimately leading to bearing failure. To support dimensional stability, manufacturers can heat-treat bearings to safeguard against bearing diametral growth or shrinkage. This prevents the retained austenite in bearing steels from changing into martensite at extreme temperatures and the martensite from additional tempering at high service temperatures.

Factors Influencing Dimensional Stability

Bearings are very precise instruments, and for them to work properly, all their parts (races, rolling elements, and cages) have to stay within tight engineering tolerances. For example, if the outer race were to expand too severely, the bearing could be in danger of wearing excessively or leaking lubricant, no longer performing properly.

As a second example, if one or more of the rolling elements were to deform, the bearing would stop running smoothly and may even jam up and fail catastrophically. Effects like these can be experienced in high-temperature environments when the expansion is significant.

Bearings have a finite design lifetime. Over time, the steel will expand, deform, or wear, impacting the bearing’s tolerances and clearances. Aging effects are normally slow and gradual; however, extreme temperatures can dramatically accelerate the bearing aging process.

At Emerson Bearing, we address this issue by guaranteeing all of our bearings to be dimensionally stable within certain operating temperatures. This means that as long as a bearing is not used above the maximum operating temperature, its critical dimensions will remain within specified tolerances for the bearing lifetime.

In a nutshell, your bearing will continue to perform as your design requires. However, at temperatures outside the guaranteed operating range, bearing life and performance should be expected to decrease according to the loading conditions and the operating environment.

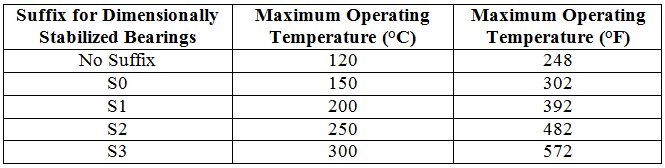

The table below lists our dimensionally stabilized categories divided by the maximum operating temperature:

Predicting Dimensional Stability

A dilatometer is an effective tool for helping us predict bearing steel's dimensional stability and reaction to heat treatment. The instrument is a highly controlled furnace operating at specific test temperatures to evaluate factors like phase transitions and thermal expansion in a test sample, measuring the impact of temperature on dimensional stability.

The dilatometer lessens the need for lengthy, expensive, full-scale trials. Instead, it is able to quickly and easily model the steel's response to tempering as well as potential ring growth. The tool's samples share characteristics with the rings, allowing us to examine dimensional stability and material hardness at different operating temperatures and ultimately gather accurate recommendations on heat treatments.

Why Choose Emerson Bearing

No matter what your application, we are here to help. Emerson Bearing has years of experience providing high-quality bearings to many different industries, and our technical team will assist you in choosing the right bearing for your application. If you need to know if your bearing can take the heat, contact us or request a quote today.

You can also visit our Catalog and Technical Toolbox web pages. These resources include information intended to help accelerate your decision-making process.