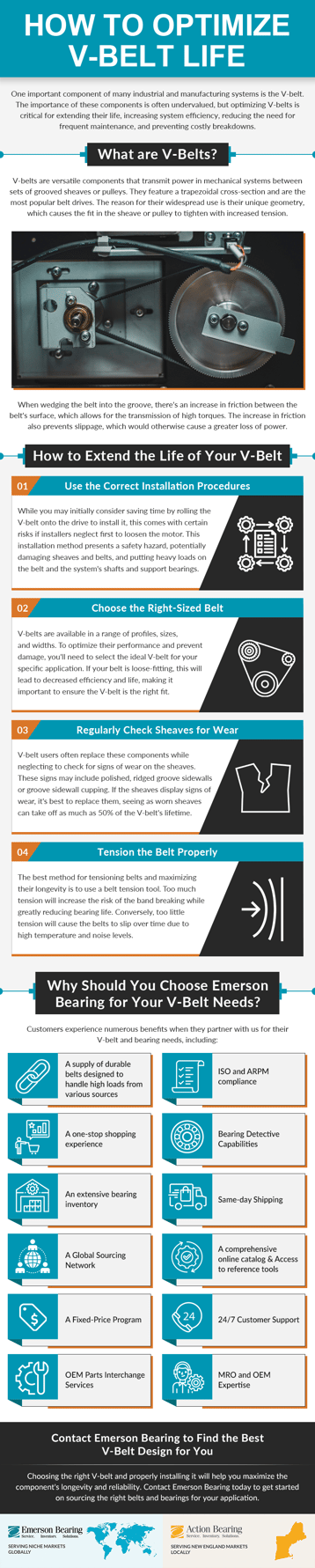

One important component of many industrial and manufacturing systems is the V-belt. The importance of these components is often undervalued, but optimizing V-belts is critical for extending their life, increasing system efficiency, reducing the need for frequent maintenance, and preventing costly breakdowns.

What Does a V-Belt Do?

V-belts are versatile components that transmit power in mechanical systems between sets of grooved sheaves or pulleys. They feature a trapezoidal cross-section and are the most popular belt drives. The reason for their widespread use is their unique geometry, which causes the fit in the sheave or pulley to tighten with increased tension.

When wedging the belt into the groove, there's an increase in friction between the belt's surface, which allows for the transmission of high torques. The increase in friction also prevents slippage, which would otherwise cause a greater loss of power.

How to Extend the Life of Your V-Belt

To extend your V-belt lifetime and boost overall V-belt quality implement the following best practices:

Use the Correct Installation Procedures

While you may initially consider saving time by rolling the V-belt onto the drive to install it, this comes with certain risks if installers neglect first to loosen the motor. This installation method presents a safety hazard, potentially damaging sheaves and belts, and putting heavy loads on the belt and the system's shafts and support bearings.

Choose the Right-Sized Belt

There have been certain technological advancements in V-belts regarding their materials, tensile cord advancements, construction methods, and cross-section profiles. They're available in a range of profiles, sizes, and widths. To optimize their performance and prevent V-belt damage, you'll need to select the ideal V-belt for your specific application. If your belt is loose-fitting, this will lead to decreased efficiency and life, making it important to ensure the V-belt is the right fit.

Regularly Check Sheaves for Wear

V-belt users often replace these components while neglecting to check for signs of wear on the sheaves. These signs may include polished, ridged groove sidewalls or groove sidewall cupping. If the sheaves display signs of wear, it's best to replace them, seeing as worn sheaves can take off as much as 50% of the V-belt's lifetime.

Tension the Belt Properly

The best method for tensioning belts and maximizing their longevity is to use a belt tension tool. Relying solely on touch to gauge tension could make it more challenging. Too much tension will increase the risk of the band breaking while greatly reducing bearing life. Conversely, too little tension will cause the belts to slip over time due to high temperature and noise levels.

Why Should You Choose Emerson Bearing for Your V-Belt Needs?

If you need help finding the appropriate V-belt for your application, the experts at Emerson Bearing are here. We prioritize supplying the right belts and bearings to each customer at the right price. We also work to ensure our customers remain consistently satisfied with V-belt quality along with the quality of our services.

Customers experience numerous benefits when they partner with us for their V-belt and bearing needs, including:

- A supply of durable belts designed to handle high loads from various sources

- ISO and ARPM compliance

- A one-stop shopping experience

- Bearing detective capabilities

- An extensive bearing inventory

- Same-day shipping

- A global sourcing network

- A comprehensive online catalog and access to reference tools

- A fixed-price program

- 24/7 customer support

- OEM parts interchange services

- MRO and OEM expertise

Contact Emerson Bearing to Find the Best V-Belt Design for You

Choosing the right V-belt and properly installing it will help you maximize the component's longevity and reliability. Contact Emerson Bearing today to get started on sourcing the right belts and bearings for your application.