At Emerson Bearing Company, we have over 50 years of experience creating high-quality ball bearings and roller bearings for commercial and industrial applications. Through both Emerson Bearing and Action Bearing, we're proud to serve markets around the world. Emerson Bearing services niche international markets, while our New England customers are served by Action Bearing, which specializes in Original Equipment Manufacturer (OEM) and Maintenance, Repair, and Operations (MRO) solutions.

Customer satisfaction is our top priority. We serve our customers by ensuring each one gets the right high-quality bearings and services at the best available price for their budget. When your project requires spindle bearings, our team will assist you in determining the ideal options for your specific needs.

What Are Spindle Bearings?

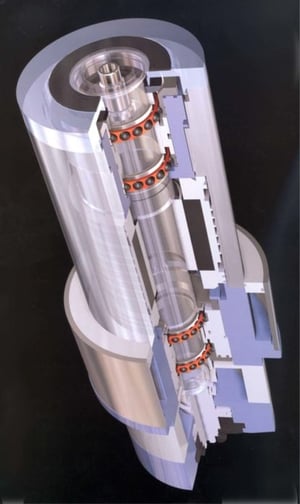

A machine tool spindle serves as a central axis, holding a workpiece or the various cutting tools that carry out machining operations in CNC equipment. Located on this component, specialty spindle bearings guide the spindle as it rotates at high speed. They also help maintain its rigidity, limiting radial or axial spindle displacement.

Spindle bearings are typically made up of inner and outer rings, balls or rollers as the rolling elements, cages to support appropriate rolling element alignment, and seals to safeguard bearing components from contaminants. They're available in multiple widths, diameters, and load ratings to suit a variety of applications and spindle designs.

You'll usually find these bearings in CNC milling, lathing, and grinding equipment, drill presses; and machine tools for industrial projects. The bearings are critical to ensuring precision and smooth rotational movement in tool spindles. By extension, they support overall equipment performance, operational efficiency, and product quality and accuracy.

Key Factors for Choosing the Right Spindle Bearings

When you're choosing ball or roller bearings for your next project, there are three key factors to keep in mind: contact angle, preload, and system rigidity.

1. Contact Angle

In an assembly, the line along which ball bearings come into direct contact with the raceways is the contact angle. The radial play and thrust loading are its determining factors. The angle should preferably be 15°, as this provides the ideal balance between radial and axial rigidity and capacity. Some systems, however, have a 25° contact angle to increase axial rigidity. Whichever contact angle you choose for your specific system, be sure to select bearings that will be compatible with operations at that specific angle.

2. Preload

This is the force that maintains pressure on the raceway and rolling element surfaces. An ongoing elastic compressive force, preload prevents parts from making uncontrolled radial or axial movements, even when experiencing load. With the appropriate bearings, your system will successfully resist breakage under this added force.

3. System Rigidity

Ball bearings and roller bearings must be capable of withstanding the various forces that machine tools produce. Bearing stiffness, housing stiffness, and related factors impact the system rigidity of a machine and its ability to consistently deliver precision results.

Common Challenges in Spindle Bearing Applications

All bearings have a pre-determined bearing life, or a maximum number of rotations the bearing can undergo. These rotations impact the inner rings, outer rings, and rolling elements with constant load, which leads to inevitable wear. Factors that can result in excessive wear and shorten the effective lifespan of the bearings include:

- Inefficient or full contact seals. The more contact a bearing has with a seal (such as a full contact seal) or the less calibrated a seal is, the more wear the bearing will undergo. This can wear the sealing element as well as the bearing.

- High speeds or speed changes. If the bearing is operating at excess speeds, the friction can quickly wear through a bearing. Also, excess speeds can increase sliding speed, which causes uneven wear. If the operation speed changes too quickly, that will increase the slip and wear.

- Poor environmental conditions. Dirt, dust, and other foreign particles can scratch the ball bearing's surface and cause wear. The presence of water can also corrode the surface, leading to poor performance and a shortened lifespan.

To learn more, read our blog on common causes of bearing failure or Emerson's guide to bearing failure analysis.

Best Practices for Spindle Bearing Installation and Maintenance

With proper maintenance and care, you can extend the life of bearings to reach or exceed the recommended service life. Two of the most important parts of caring for ball and roller bearings include cleaning the bearings and reapplying grease. Incorporate these tips to extend your equipment's lifespan:

- Grease storage. Always keep grease tins closed when not in use and keep the containers in a separate storage environment with stable temperatures. We recommend not using grease that's more than three years old.

- Grease application. Once the bearings have been cleaned and completely dried, apply grease over the balls and rings. Be sure an equal amount of grease gets between the balls in the inner ring. To ensure the grease is as clean as possible, always apply it with clean spatulas or clean plastic syringes for precise applications.

Working With an Industry Leader in Emerson

We know that getting the best possible performance out of your equipment relies on having high-quality ball and roller bearings from the start. Our team is here to help you find the bearings with the right specifications for your facility's sensitive tools and equipment. We maintain an extensive inventory of bearings for countless high-speed and high-precision applications. Our selection also includes next-generation bearings made from specialty steels.

If you want to ensure maximum performance of your equipment's bearings, start with a professionally sourced, high-quality selection from the international experts at Emerson. We can help your team find the ideal ball and roller bearings for any application to ensure a long service life.

To see how our team can help with your bearing selection process, please contact us or request a quote today.