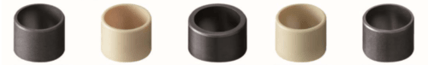

While metal bearings/bushings are common on the market today, there are certain applications that benefit from plastic bearings/bushings. These versatile components can take any number of forms and range considerably in style to work for the proper application.

Plastic bearings present a low-cost, low-maintenance, and easy-to-customize solution in a variety of settings. Their customizability is perfect for specialized applications and their flexibility makes them ideal for manufacturers who have a specific design in mind.

Since plastic bearings are resistant to dirt, dust, and chemicals, they require minimal maintenance. This is helpful for applications where maintenance may be infrequent or impossible. They also withstand corrosion with ease—and, as a bonus, they don’t require lubrication to function effectively.

This exceptional product’s longevity translates to cost-savings for our clients. Each bearing can be utilized for longer than its metal counterparts and may be employed in a variety of applications. These low-maintenance plastic bearings require fewer replacements and a much smaller investment than alternative products.

Customizable

Plastic bearings’ customizability positions them as a component of choice for many seasoned industry experts. Because plastic is such a widely available and inexpensive material, creating and manufacturing custom designs is economical and simple.

Many of our clients appreciate plastic bearings for their unique design flexibility. Rather than forcing parts and equipment to work together, we opt to manufacture bearings with devices in mind. Standard bearings made of other materials drastically reduce flexibility and freedom in the workplace.

The varied customizations of plastic bearings is evident by the wide range of applications that use them, including:

- Bottling equipment

- Conveyor systems

- Fillers

- The food industry

- Hoppers

- Mixers

- Packaging arms

- Product lines

- Projects that utilize harsh chemicals or salt water

- Single machines

- Wash down

Low-Maintenance

Plastic bearings are self-lubricating, which means organizations that rely on them never have to worry about funding the purchase of costly, specialized lubricants. This also eliminates the need for frequent servicing, which cuts costs and simplifies the work and maintenance processes.

Many customers utilize plastic bearings in wash-down applications because of their water-resistant properties. Even projects that involve salt water or harsh chemicals employ plastic bearings without compromising performance. These bearings provide the ideal alternative to bronze, metal-backed, and simple plastic injection-molded bearings.

Their constant and consistent low coefficient of friction also helps cut maintenance and reduce costs. A low COF allows for long service lives and minimal maintenance, rendering plastic bearings the ideal “fit-and-forget” components.

Low-Cost

Opting to utilize plastic bushings in place of their metal counterparts reduces overall costs by as much as 40%. Their wear resistance translates to low-cost maintenance and infrequent replacements. These bearings also allow for the use of inexpensive shafts, which can cut project costs.

Thanks to plastic bearings’ low COF and high wear-resistance, they often last longer and cost less than their more mainstream metal counterparts. The switch from metal to plastic can save industry professionals significant funds long-term.

Emerson Bearing’s Plastic Bearing Products

Plastic bearings often are the ideal solution in applications where low maintenance and chemical-resistance are key. These products resist temperatures as high as 482 F, manage high loads, and function in wet environments. FDA-approved plastic bearings provide a low-cost alternative to their less effective counterparts.

The Emerson team has worked to provide domestic and international OEM and MRO markets with high-quality ball and roller bearing products. Our 25,000 square foot warehouse is always fully stocked with a wide range of bearings, including composite plastic bearings, that are suitable for all industries.

If you’re interested in learning more about the benefits of plastic bearings, contact us today! We stand behind our plastic bearing products and are proud to offer the highest quality components found in the industry.