Specialty steels – also referred to as alloy steel – contain additional alloyed materials that deliver special properties to the final product. Specialty steels are engineered to provide superior performance under specific conditions. For bearings such as roller bearings and ball bearings, specialty steels would be selected versus other bearing materials to deliver properties that can best withstand the operating conditions the bearings will be exposed to.

Various stainless steel alloys are included among common specialty steels. Typically, standard bearings are fabricated using chrome steel, which can be heat-treated and ground to deliver durability and high load capacity, allowing the bearings to perform well in broad applications.

Depending on the operating conditions of the ball bearing or roller bearing, other specialty stainless steels may offer better performance. For specific applications, alloy steels can deliver a range of beneficial properties.

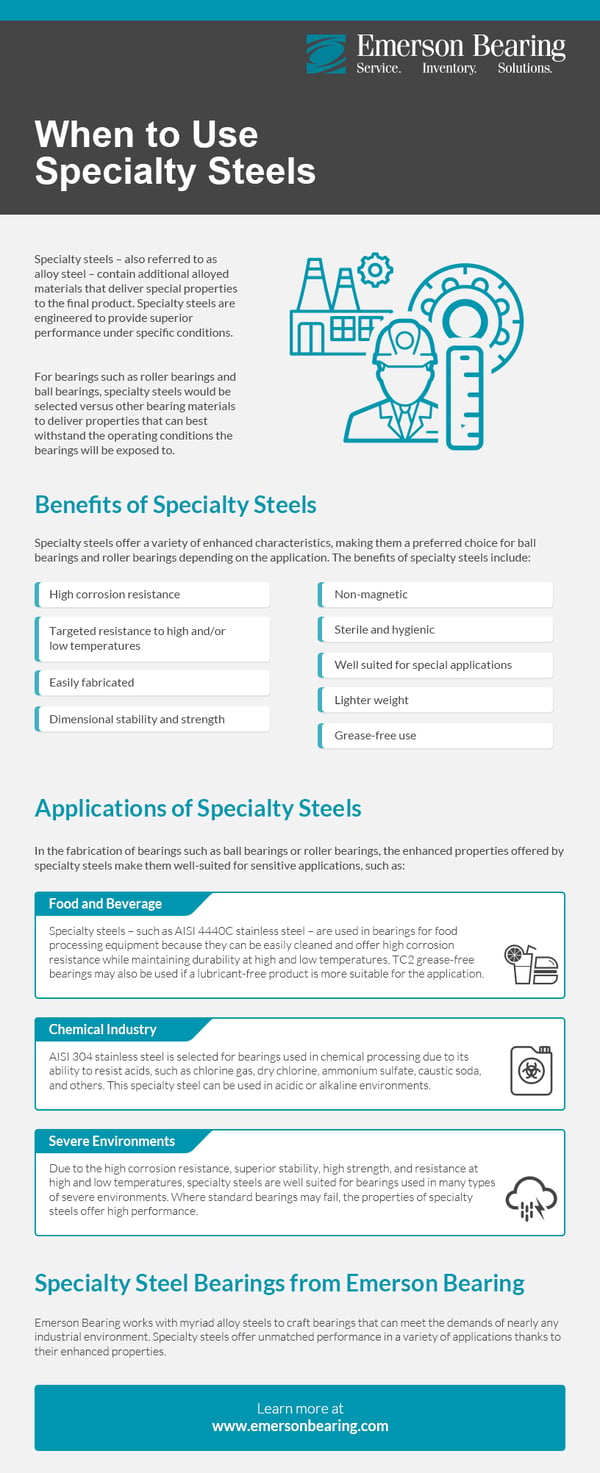

Benefits of Specialty Steels

Specialty steels offer a variety of enhanced characteristics, making them a preferred choice for ball bearings and roller bearings depending on the application. The benefits of specialty steels include:

• High corrosion resistance

• Targeted resistance to high and/or low temperatures

• Easily fabricated

• Dimensional stability and strength

• Non-magnetic

• Sterile and hygienic

• Well suited for special applications

• Lighter weight

• Grease-free use

Applications of Specialty Steels

In the fabrication of bearings such as ball bearings or roller bearings, the enhanced properties offered by specialty steels make them well-suited for sensitive applications, such as:

• Food and Beverage

Specialty steels – such as AISI 4440C stainless steel – are used in bearings for food processing equipment because they can be easily cleaned and offer high corrosion resistance while maintaining durability at high and low temperatures. TC2 grease-free bearings may also be used if a lubricant-free product is more suitable for the application.

• Chemical Industry

AISI 304 stainless steel is selected for bearings used in chemical processing due to its ability to resist acids, such as chlorine gas, dry chlorine, ammonium sulfate, caustic soda, and others. This specialty steel can be used in acidic or alkaline environments.

• Severe Environments

Due to the high corrosion resistance, superior stability, high strength, and resistance at high and low temperatures, specialty steels are well suited for bearings used in many types of severe environments. Where standard bearings may fail, the properties of specialty steels offer high performance.

Specialty Steel Bearings from Emerson Bearing

Emerson Bearing works with myriad alloy steels to craft bearings that can meet the demands of nearly any industrial environment. Specialty steels offer unmatched performance in a variety of applications thanks to their enhanced properties.

If you’re looking for more information on bearings suitable for use in severe environments, download our free eBook for more information.