While metal bearings/bushings are common on the market today, there are certain applications that benefit from plastic bearings/bushings. These versatile components can take any number of forms and range considerably in style to work for the proper application.

Emerson Bearing Blog

Making beer is no small feat. It is both an art and a science that requires precise measurements

and the right equipment to create and re-create beers that consumers will love. What was once a

task reserved for giant alcoholic beverage manufacturers has become a labor of love for many

small brewers who created a craft beer movement across the country. Today's independent

brewers rely on a variety of other industries to get high-quality ingredients, machines, bottles, and more.

Oil seals, also known as grease or dirt seals, are an essential component of many machines and pieces of industrial equipment. An oil seal is designed to retain grease in a case or housing and close the gaps between stationary and moving components in pieces of machinery.

An example of this in the automotive industry is the seals within gear boots that enclose a car’s CV axles. Of course, there are many different applications across industries in which oil seals prevent the escape of vital lubricants and ensure the continued smooth operation of the machine in question.

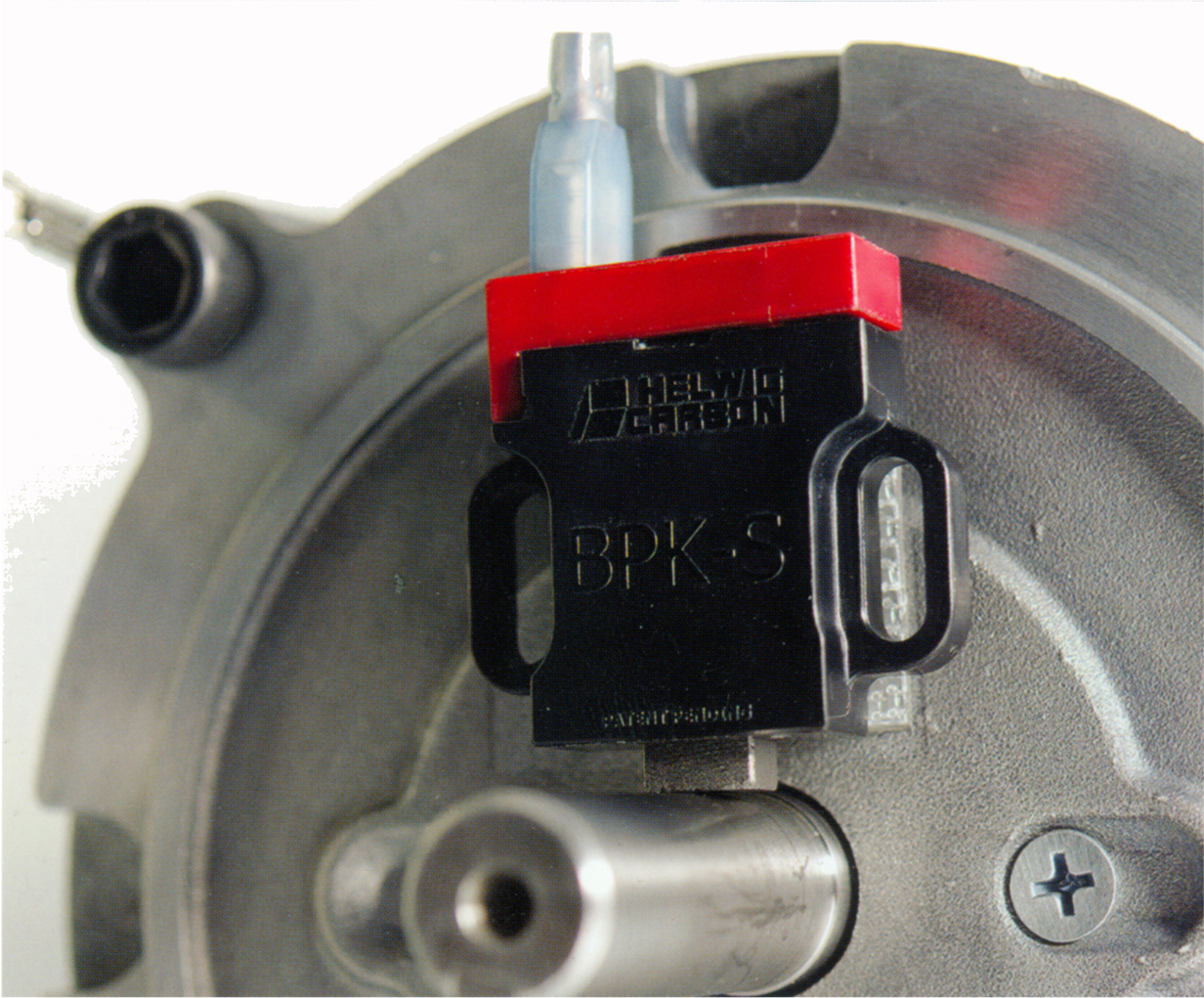

Exposing a bearing to an electric current can cause electrical bearing damage. The damage manifests as pits and grooves on the bearings' surface create an uneven surface texture causing additional noise, vibration, and (eventually) complete failure. These outcomes can be costly, often leading to unnecessary downtime and expensive repairs or upgrades.

Although not all bearings are damaged by an electrical current and not all circuits cause bearing damage, there are two situations in which the problem typically occurs: when equipment is grounded incorrectly or when bearings are used in AC/DC motors with variable frequency drives (VFDs).

Motor shaft voltages have the potential to damage the components around them. If a shaft’s voltage exceeds the insulation capabilities of nearby cables or parts, it can cause both long-term and acute damage to motor bearings.

Some high voltages can even lead to arcing between the shaft and the bearing. When this occurs, the arcing rapidly elevates the temperature of the bearing. Metal can vaporize and become permanently damaged and pitted from this process.

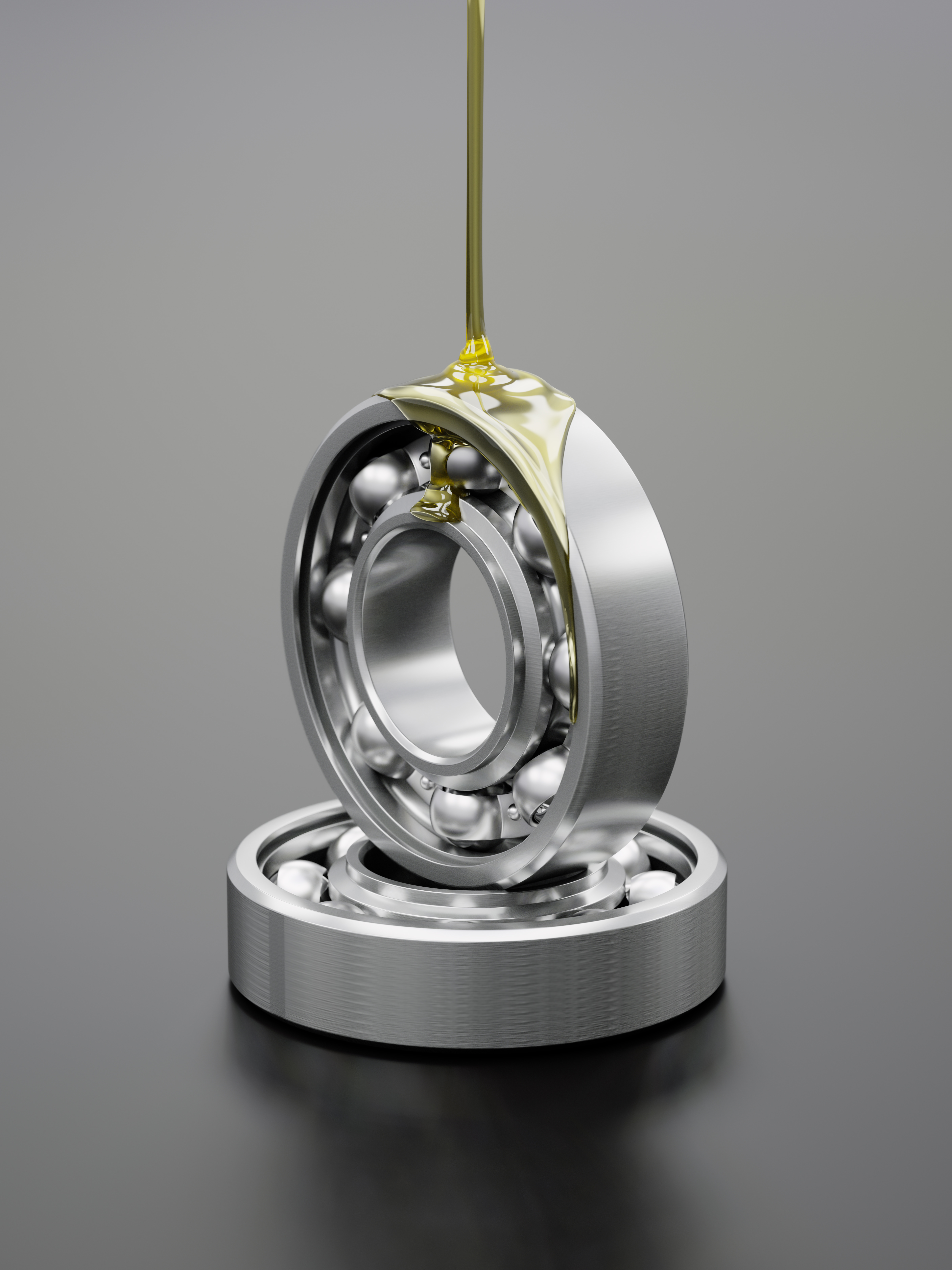

To perform at optimal levels, bearings require sufficient lubrication. When properly applied, lubricants can reduce friction, which reduces the amount of wear and tear experienced by the bearing part. Additionally, some types of lubricants can provide recirculation which serves as a cooling method, while other types can help to disperse heat buildup to improve system performance.

All of these characteristics help prevent damage to the bearing, as well as prolong its overall service life.

When selecting bearings for your next project, there are three key factors to consider, which are also a function of the load being carried and the limiting or speed required. The friction, temperature, and lubrication involved in a system and its environment directly impact bearings, so it’s critical to select a bearing that has the proper tolerances for your application.

Specialty steels – also referred to as alloy steel – contain additional alloyed materials that deliver special properties to the final product. Specialty steels are engineered to provide superior performance under specific conditions. For bearings such as roller bearings and ball bearings, specialty steels would be selected versus other bearing materials to deliver properties that can best withstand the operating conditions the bearings will be exposed to.

For any application that requires a device with rotating or rolling components, the choice of both bearing and seal is essential.

Be the first to know about all things bearings!

Subscribe to our blog to receive the latest company and industry news right in your inbox

.jpg)