From the simplest home appliance to the most complex industrial equipment, precision engineering is essential for safe, reliable moving parts. Connections must allow unrestricted movement, which is where roller bearings come in. Like ball bearings, roller bearings are meant to minimize friction while managing a load, but instead of having point contact, roller bearings have line contact. This gives them greater shock resistance and capacity, and they come in a variety of shapes, including cylindrical, tapered, spherical, and needle profiles, to suit various applications.

Emerson Bearing Blog

Manufacturing for the recreation industry requires special considerations. Fishing gear, recreational vehicles, amusement park rides, ski area equipment, and more must be carefully designed and built to last with durable, trustworthy bearings that can withstand extreme conditions such as high impact forces, heavy moisture, and abrasion. At Emerson Bearing, we provide precise, reliable bearings for everything from go-karts to bowling pit setters. Regardless of your needs, we can deliver the right bearing at the right price.

Many industries focus on food. For example, the agricultural industry handles growing, harvesting, and preparing fruits and vegetables for distribution, while the foodservice industry handles preparing and serving meals at restaurants. Both of these industries are distinct from the food processing and packaging industry, which deals with food after it has been processed by the agricultural facilities but before it is distributed to foodservice facilities. Basically, any food that enters a production facility is within the domain of the food processing and packaging industry.

Topics: Food processing and packaging

Constant friction within bearings creates heat. Over time, this will deteriorate the bearing, significantly shortening its life. Bearing lubrication plays a vital role in separating the moving parts, minimizing friction and preventing ongoing wear and tear. As such, bearing lubrication is one of the most important aspects in maintaining and prolonging the life of the bearing. Lubricants also serve to reduce corrosion and protect against contaminants that would otherwise damage the bearings. By including inspection and regular lubrication in bearing maintenance, it is possible to improve the functionality and reliability of every bearing, reducing the risk of corrosion-based failures.

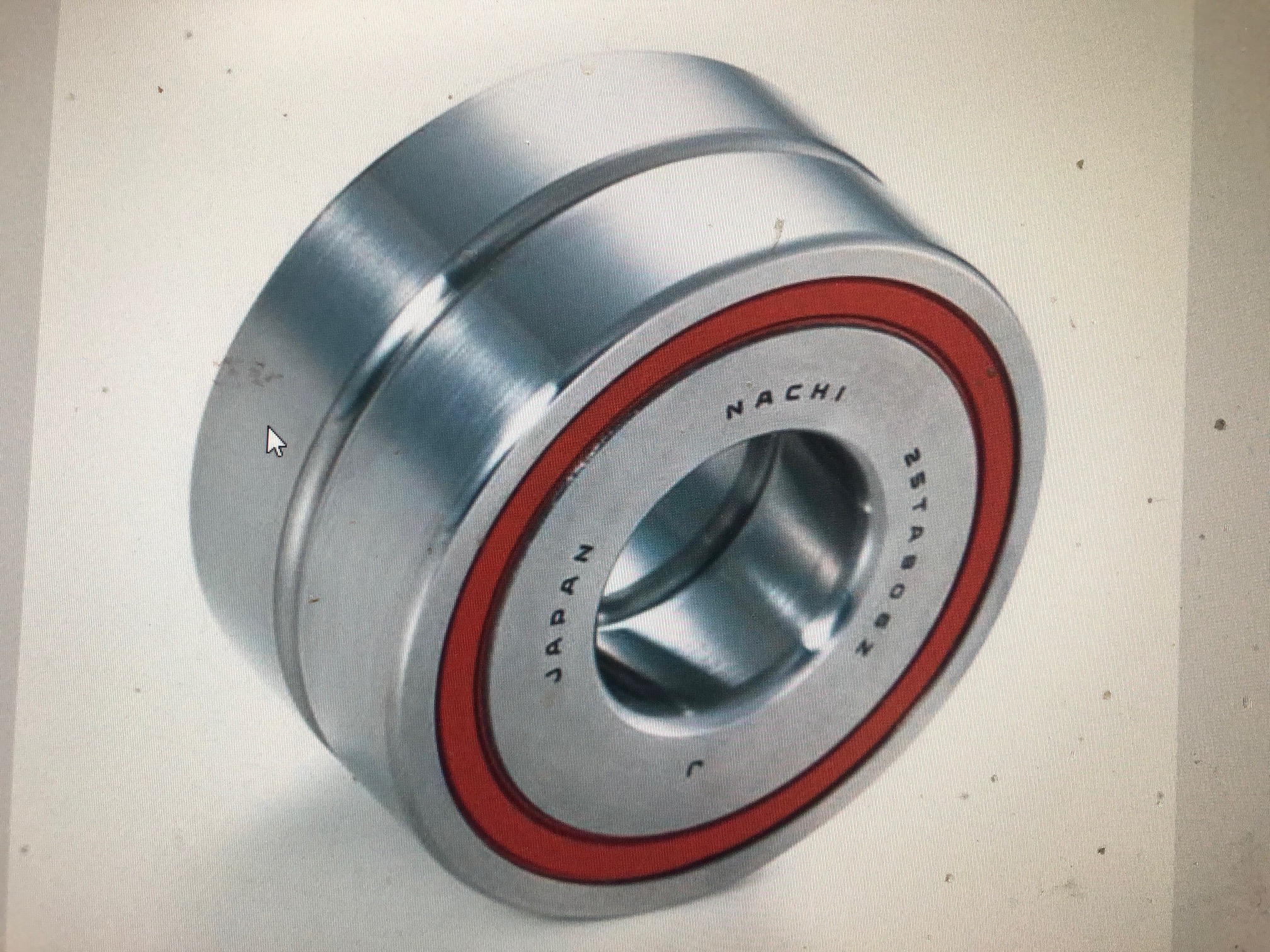

Modern machine tools are used to shape parts from wood, ceramic, metal, and other materials into a desired shape or form. For optimal accuracy and reliability, machining equipment requires high quality precision bearings, such as ball screw support bearings. Known for their durability and long lifespan, ball screw support bearings offer superior axial strength and the ability to tolerate high thrust loads without sacrificing accuracy, making them well-suited for high performance actuators.

Topics: emerson bearing, bearings

Due to advancements in software development and networking technology, it is now easier than ever to implement efficient robotics and automation solutions. Automation is continually growing within three main classifications: fixed automation, programmable automation, and flexible automation.

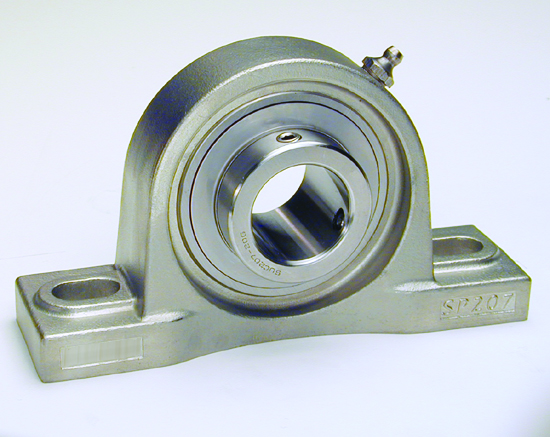

Emerson Bearing's IP69K Series bearings are designed to withstand harsh operating conditions, including high pressure caustic washdowns and other sanitization processes commonly used in food and beverage applications. This safe, reliable, and effective sealing device has a unique triple-lip and molded rubber composition, which provides superior protection against water and dust, while its “lubed for life” feature eliminates grease zerks, lube holes, and other potential intrusion areas.

Precision slewing ring bearings are a type of angular bearing that consists of two concentric rings with balls or rollers that enhance movement in load-bearing and power transmission applications. The two rings may be constructed with toothed gears to increase torque and can facilitate movement in any direction from the center of the bearing. They are ideal for use in low-speed, heavy load applications such as construction and excavation, or more intricate and precise such as medical tools and devices. Overall, there are many benefits to using precision slewing rings bearings.

Bearings are used extensively in the food and beverage industry as components in a variety of food processing and packaging machinery. Food-grade bearings must endure extreme conditions in many applications, so the life and performance of bearings used in these applications are influenced largely by the decisions of designers and engineers. Design considerations that may impact a bearing’s durability in food-grade applications include material, lubrication type, and shielding options.

In the machine tool industry, spindles are a critical component used to shape materials through the use of high-speed rotation and pressure. As modern machinery advances, machining equipment is required to be faster, more precise, and more durable than ever before. Bearings are crucial parts that direct and enhance spindle movement. The use of high quality bearings, improves the efficiency and reliability of machine tool spindles, thereby increasing production and reducing wear and tear on machinery.

Be the first to know about all things bearings!

Subscribe to our blog to receive the latest company and industry news right in your inbox