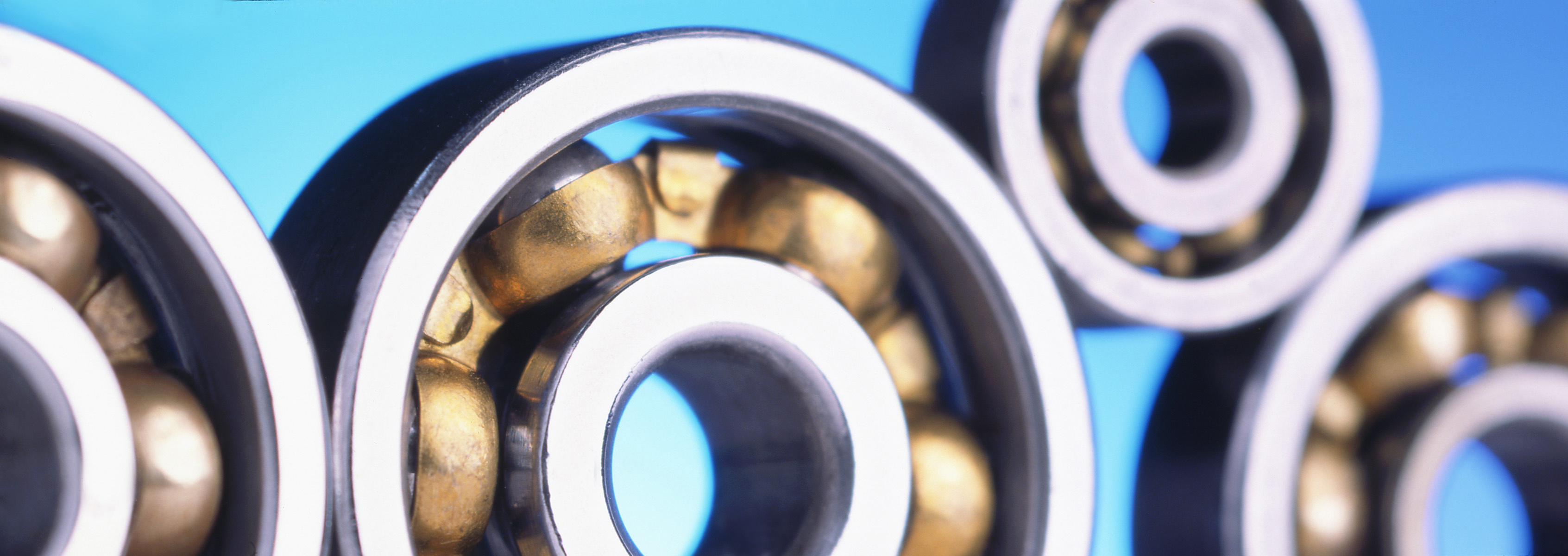

Bearings improve efficiency in linear and rotational movements by reducing friction and supporting loads. The materials used to make bearings impact the applications to which they are best suited and how they perform.

Emerson Bearing Blog

Emerson Bearing is a leading supplier of high-quality ball and roller bearings. We have established and maintained our reputation for over five decades, delivering bearings to global and domestic customers. Our team of experts ensures each customer receives the most suitable bearings for their application. One of the major industries we serve is robotic automation. Read on to learn about our precision bearings for robotic applications.

Topics: precision bearings, bearings

Having Bearing Challenges? Talk with Emerson: Solve Your Pricing, Delivery & Technical Issues

Posted on November 23, 2022

A detailed understanding of bearings is crucial for selecting and sourcing the correct bearing. It's difficult for a customer with little or no knowledge of bearings to make the right decision. That's why it's best to partner with a company or service with experience in sourcing, pricing, and delivering bearings.

Topics: bearings, ball bearings

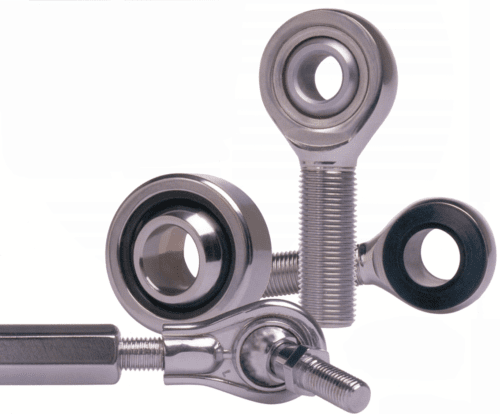

Rod ends consist of an eye-shaped head with an integral shank that serves as housing for a spherical plain bearing, or bushing. They are utilized in linkage applications where a bearing must support a significant misalignment. Rod ends are typically used in the automotive and aerospace industries, but they are also present in a wide range of industrial machinery.

One important component of many industrial and manufacturing systems is the V-belt. The importance of these components is often undervalued, but optimizing V-belts is critical for extending their life, increasing system efficiency, reducing the need for frequent maintenance, and preventing costly breakdowns.

Roller bearings are important components in most machines. If roller bearings are damaged, other machine parts or the products they produce can be compromised. Like ball bearings, roller bearings are designed to carry loads and minimize friction. It’s common for roller bearings to experience some abrasion over time that requires replacements or repairs. Here you’ll learn the most common causes and types of roller bearing damage to help you prolong equipment life.

Topics: roller bearings, bearing maintenance

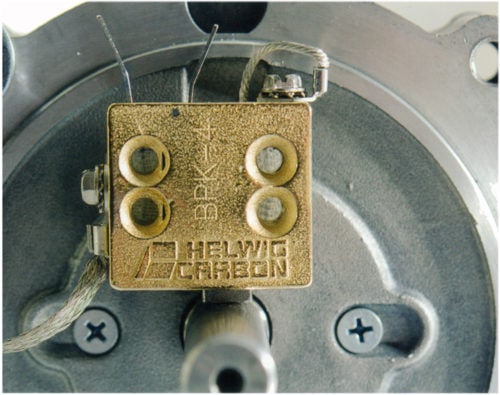

Shaft grounding devices, or shaft earthing devices, redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Motors can act as electromagnetic dynamos, with fast-moving parts creating voltage that is not harnessed for productive use. These currents build up mainly on the motor shaft, but they also circulate throughout the rest of the motor. By properly grounding a motor shaft with a shaft grounding device, the wear on motor bearings and other components is greatly reduced, ensuring that the motor lasts longer and functions more effectively.

Oil seals are vital to the daily operation of most factories and a wide range of industrial and commercial equipment. They are available in imperial and metric dimensions for both single- and double-lip design. Motors, Mechanical Hydraulic systems, pistons, and pumps utilize oil seals to protect internal components. Depending on the application, there are various material, size, and configuration options to best fit your needs. Learn more about oil seals, their composition, and the wide range of advantages they offer for your equipment.

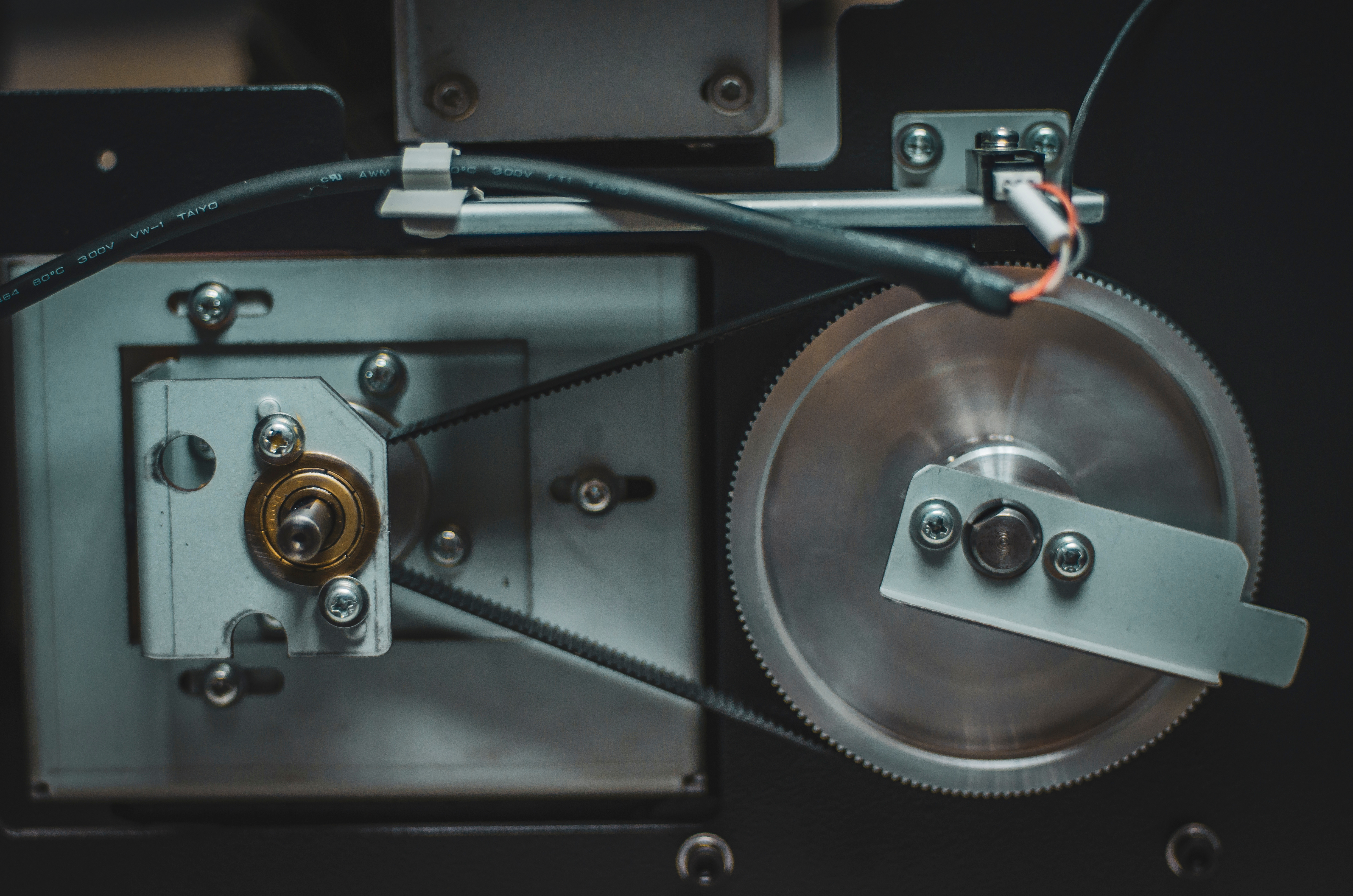

Despite more printed products going digital, the paper industry remains a constant. In just the United States, the paper printing and conversion industry is worth $400 million or more. Paper conversion is the procedure in which we convert raw paper materials into the products we use every day. Paper has nearly endless applications in the residential, commercial, and industrial sectors. To meet this high demand, we need efficient processes and equipment. Technology in the paper conversion industry relies on bearings as they allow companies to achieve precision, accuracy, and uninterrupted performance.

There is a vast array of bearing types and sizes for a good reason: every application has unique needs and specifications, and it’s important to use the right bearings for the job. When you work with a trusted bearing provider, you’ll have a large inventory of roller bearings, ball bearings, contact bearings, and more to choose from, and you’ll have the opportunity to create custom solutions. Your provider should be able to source and distribute your bearings quickly and efficiently, help you make decisions, and offer you the same standard bearing at various price points depending on where it’s being sourced from.

Topics: bearings, bearing rating, cost-effective

Be the first to know about all things bearings!

Subscribe to our blog to receive the latest company and industry news right in your inbox